Wind tunnel for environmental experiments

The project’s goal: establishment of a unique in its field building for fulfillment of environmental research. The building includes areas of laboratories, offices and technical spaces. The project was designed and implemented in cooperation with academics from the Technion, leading architectural planning agencies, civil engineers, air conditioning experts and mechanical engineers. Manufacturing was carried out by plants in Israel’s periphery.

A unique wind tunnel was built in the building, enabling experimentation in changing environmental conditions. The air entering the tunnel is treated in air handling units, within the ambient temperature range of 5-45 ° C, humidity varies in the range of 20%-80% and the wind in a laminar flow, ranging from 0.5 m / s to 10 m / s.

These climatic conditions are monitored and controlled continuously using advanced equipment.

During the experiments, measurements are carried out along the tunnel in different cross-sections. This is made possible by a system of internal and external axels, on which sensors have been installed. The system was developed for the facility by assistance-field personnel in collaboration with the research team. In addition, the tunnel is equipped with a rotating table, which allows the rotation of the structural models and simulation of wind from different directions, while conducting the experiment.

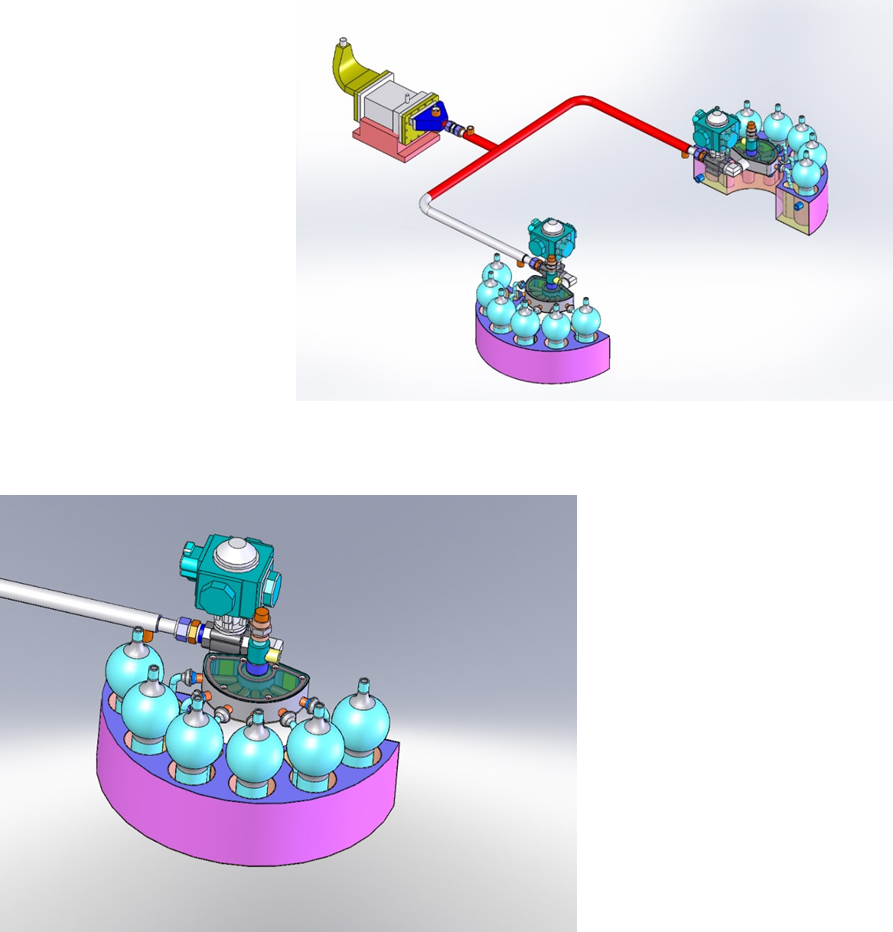

System model (Vaporizing and purifying)

The model system was developed in collaboration with IIBR’s Organic chemistry department in order to establish a database of vaporization of hazardous substances from various surfaces under different conditions.

The system assists in preparing models for risk assessment and in improvement of existing models. In addition, it enables assessment of the purification efficiency of existing purification agents and the collection of information on the effectiveness of novel purification agents.

The system is comprised of a sealed and controlled evaporation chamber into which samples of surfaces contaminated with test materials are inserted. During the test, air is controlled in accordance with the required flow, temperature and humidity above the test surface. The air that flows through the suction line into the evaporation chamber is treated and adapted to the experimental requirements.

Control of the system is carried out through proportional valves, sensors, controllers and a computer that stores the data throughout the experiment.

During the experiment, air sampling is carried out using glass balls or SPE tubes and samples are transferred for enzymatic analysis.

Unit of evaporation and sampling:

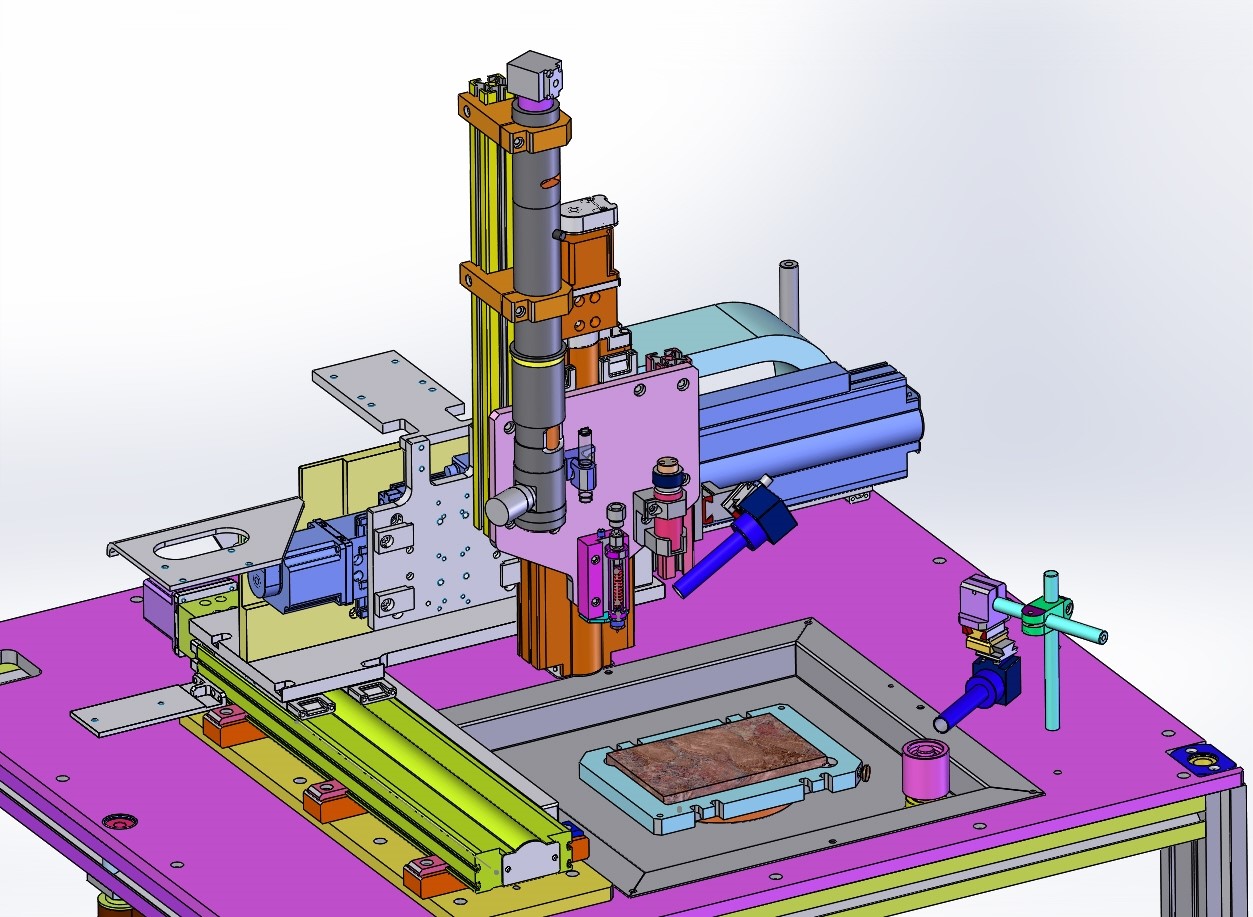

Uniform dispersion of Chemistry solutions’ SYSTEM

The system was developed at the Institute in collaboration with IIBR’s Physical Chemistry department and was designed for uniform dispersion of aqueous solutions and organic solutions in tiny droplets.

The process is performed by means of a piezoelectric spray (ink-jet technology), which sprays tiny droplets of varying sizes in the range of 30-80 microns, depending on the type of sprayer. A dedicated controller is used to control of the size of the droplets by changing the voltage and current levels.

The system can disperse droplets of tens microns in a given area. The density of droplets to defined area is determined by an X.Y.Z coordinate system, which is controlled by dedicated software written for this purpose.

The process is controlled and supervised by a camera and a telescope.

Exposure system for evaluation of detectors

The detector system is a unique system that was built in collaboration with IIBR’s Physical Chemistry Department. The system is used for testing and developing detectors for identification of various hazardous substances and mixtures of liquid and gas substances.

The system is universal and enables testing of a wide range of detectors. Each detector type is equipped with an experimental device or a dedicated exposure cell, according to experimental needs. Sampling is performed during the experiment.

The air that flows through the system is controlled for flow, temperature and humidity, enabling experiments to be carried out in environmental conditions.

The process is supervised using controllers and a control computer.

Image: exposure device for a chemo-resistor detector

Exposure system for evaluation of detectors

Dynamic Inspection System

A unique flow system designed to test the permeability of hazardous component materials used in protective equipment such as: protective clothing, masks, sealed suits, gloves, cover sheets and more.

To ensure the conditions of the experiment, the system was installed in a controlled chamber that swirls air in laminar flow. The conditions in the flow system are controlled for temperature and humidity.

The samples being tested are inserted into designated permeability-testing chambers and are exposed to different concentrations of agents under controlled conditions. The polluted air is sampled continuously by detectors, located in front of and behind the tested sample. The system is controlled by a dedicated data collection and control software.