Switching to electrical operational vehicles

Several operational vehicles, powered by diesel and gasoline, were used at the Institute, and due to natural wear and aging, we were required to replace them with new generation vehicles.

It was found that the switch to an electric vehicle reduces the annual costs of maintenance and fuel, the vehicle does not emit pollutants into the air and reduces environmental noise. In September 2015, a license was issued from the Ministry of Transport to electric operational vehicles and today, the Institute is at the process of gradually switching all the Institute's operational vehicles, to electric ones.

Maintaining a collected-water recovery system

In order to optimize and reduce water consumption, the Institute has designed and established a unique system for recovering collected water. The Institute has 4 water treatment systems that use reverse osmosis. With this method, water is discharged into the central sewage at a rate of about 30% of the feeding water. In addition, the Institute has a large number of air treatment units, which remove, among other things, the water vapor from the air and dry it through cooling. This process produces water condensation that is transferred into the sewer.

Storage and treatment of the concentrate water and the condensation water from the air treatment units, enable water reuse for irrigation and reduction of water consumption at the Institute.

The system delivers water by gravitation, without the use of a pump, into a container. Water is monitored continuously to ensure the quality of water required for irrigation. The flow of water from the tank is carried out by a pump according to the timetables and quantities defined.

The system enables savings of about 1 cubic meter of drinking water per hour.

Reduction of energy losses from boiler’s casing

Steam at the Institute is produced by using diesel-powered boilers.

The heat emitted by the steam system causes thermal losses, resulting in increased fuel consumption, loading of the cooling system and the emission of unnecessary pollutants.

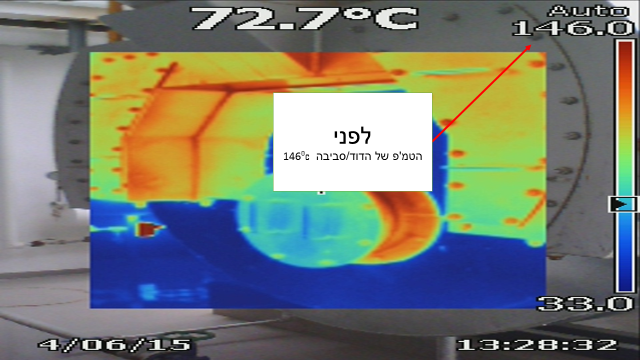

In order to quantify the extent of energy losses, non-insulated steam valves were photographed using a thermal camera.

During the flow of steam, the temperature in the valves ranges from 150-160 ° C, the energy is lost to the environment in radiation and in flow (wind).

The potential for financial savings is calculated by a specialized software - which uses the surface of the device, the type of metal, wind speed and temperature as source data for calculation.

An examination of the energy losses to the environment was carried out, which was translated into annual consumption.

All the steam valves and accessories were isolated, following which, significant savings were achieved in annual diesel consumption.

The following is an example of thermographic mapping (before and after)

Switching to LED lighting and installing presence detectors

As part of the energy efficiency program, it was decided to replace all lighting fixtures throughout the Institute with LED lighting.

LEDs are energy efficient bulbs with a power consumption of about 45% less than standard incandescent light fixtures.

In addition, presence detectors were installed to turn off lighting and air conditioners automatically in empty rooms without the need for changing habits or behavior patterns.

Upgrading central air conditioning units

The institute has central air conditioning units whose function is to convert electrical energy into cooling or heating.

For the purpose of optimizing, saving and protecting the environment, the Institute has initiated processes to upgrade the units to systems with high energy efficiency that use “green” gas as coolant.

Using Astronomical clocks

The outdoor lighting at the Institute is controlled by astronomical clocks, which allow accurate illumination times, according to the sunrise and sunset hours and save electricity.

Picture of an astronomical clock